Actuated & Control Valves

Actuated valves and Control valves

Product Description

Actuated valves and control valves are essential components in industrial processes, used to regulate the flow or pressure of fluids or gasses. While both serve similar purposes, there are key distinctions between them.

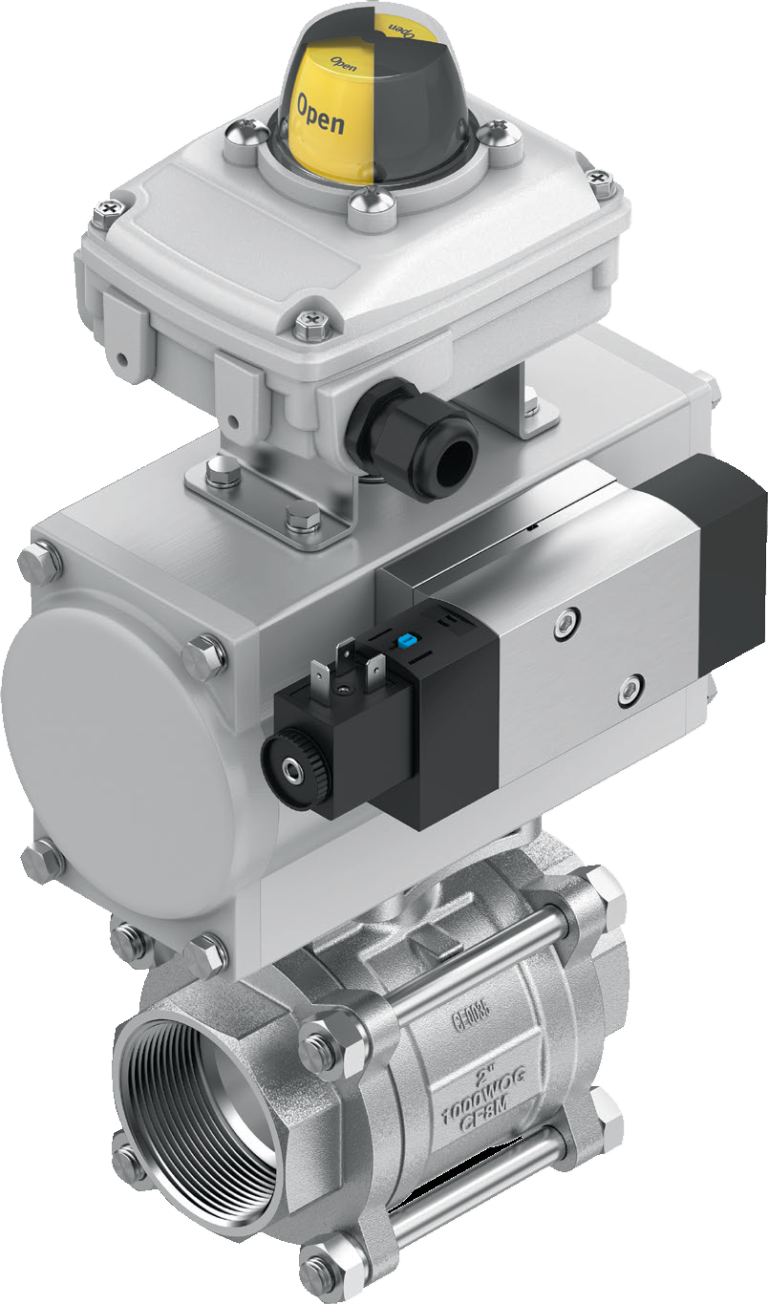

Actuated Valves

- Definition: These valves use an external force or mechanism to open or close. This force can be provided by various actuators, such as pneumatic, hydraulic, or electric.

- Functionality: Actuated valves often perform simple on/off functions or maintain a specific position. They are not designed for precise flow control.

- Examples: Gate valves, ball valves, Butterfly valves and plug valves are common types of actuated valves.

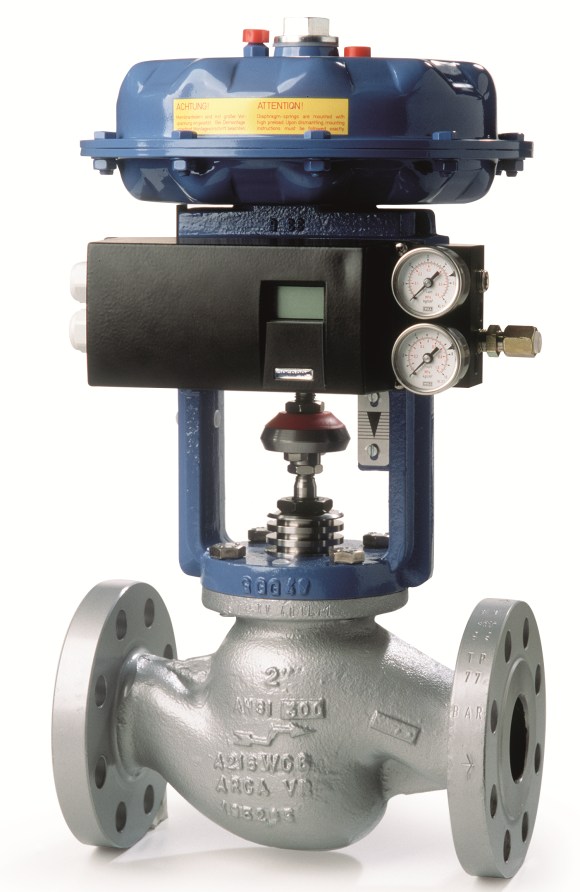

Control Valves

- Definition: Control valves are a specialized type of actuated valve designed to regulate flow rates precisely based on a control signal.

- Functionality: These valves use a controller to receive a signal (e.g., from a process variable sensor) and adjust the valve position accordingly. This allows for precise control of flow rates, pressure, temperature, or other process parameters.

- Examples: Globe valves, butterfly valves, and diaphragm valves are often used as control valves.

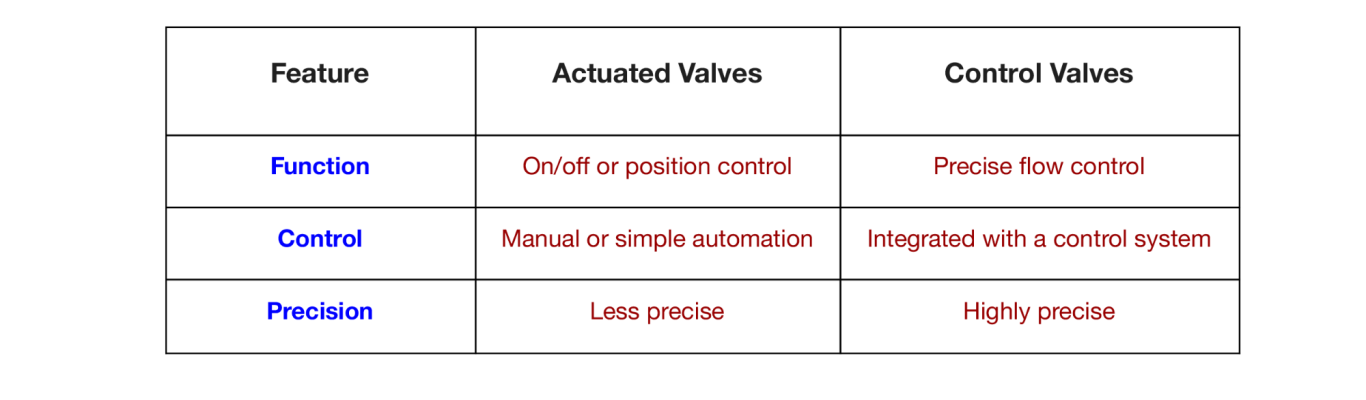

Key Differences: Actuated valves are used for basic flow control, while control valves provide precise regulation based on external signals. The choice between the two depends on the specific requirements of the process.

Applications

Control valves are widely used in industries such as:

- Chemical processing

- Oil and gas

- Water treatments and water networks

- Power generation

- Food and beverage

Technical Specification

Actuated and control Ball Valve

Size Range: DN08-DN1500 (1/4"-60")

Body Materials: Carbon Steel, Stainless Steel, Bronze, Duplex, Super Duplex

Body Type: Floating Ball, DBB, Fully Welded

Applications: Chemical, Marine, Food/Beverage, Consumer Health, Petrochemical, Oil & Gas, Water

End Connections: Flanged, Screwed BSP/NPT, Socket Weld/Butt Weld, Hygienic Tri Clamp/Weld OD

Pressure Rating: PN10-PN420, ANSI 150-ANSI 2500, 1000-6000 WOG

Actuated and control Butterfly Valve

Size Range: DN32-DN1600 (1 1/4"-64")

Body Materials: GJS500-7 Ductile Iron Rilsan Coated

Disc Materials: CF8M Stainless Steel

Seat Materials: EPDM, NBR Buna, Hypalon, Viton, Silicone, High Temperature, Polyisoprene, Epichloridine

Actuated Function: Pneumatic, Electric, Fail Safe, Spring Return, Battery Backup, Double Acting

Applications: Potable/Wastewater, Cooling Systems, Oil, Gases, Air

Globe Control Valve

Size Range:1/2" to 20"

Ansi Class: 125 to 2500

Body Materials: Cast Iron, Carbon Steel, Stainless Steel, Monel, Hastelloy, Cast Steel (A352 LCC) & More

Actuated and control Knife gate Valve

Size Range: DN50-DN600

Body and seat Materials: Cast iron body - NBR seat - Cast iron body - EPDM seat - Cast iron body - Metal sea

Disc Materials: CF8M Stainless Steel

Actuated Function: Pneumatic

Competitive advantages

Technical knowledge and wide range of suppliers

According to the type of fluid and the working and environmental conditions of the valve, process needs and project limitations, the most suitable components from among hundreds of valve, actuator, positioner, transmitter and sensor manufacturers are provided and all necessary installation accessories and couplings are designed and produced and finally the final product is assembled, tested and delivered to the customer.

All necessary certificates can be obtained on the final product.

Our technical knowledge and being fully familiar with the products of world-renowned manufacturers and offering ready-to-install products to customers is our competitive advantage.

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.